Cloth Materials

We offer premium book cloths for hardcover cases, slipcases, and specialty packaging. Choose from smooth or woven textures in a wide range of colors—compatible with foil stamping, debossing, and screen/UV printing—to suit diverse production and design needs.

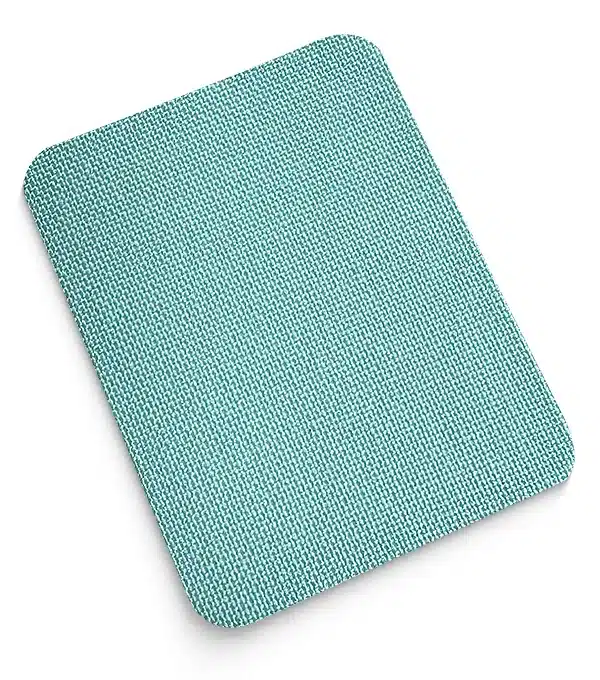

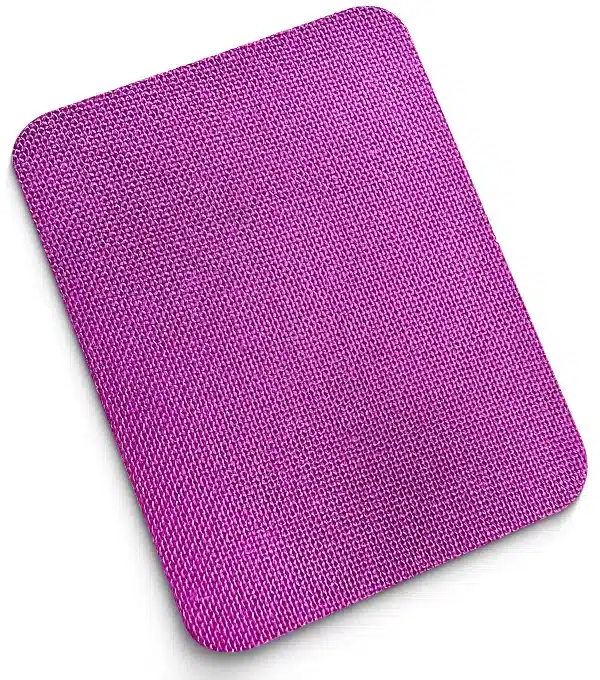

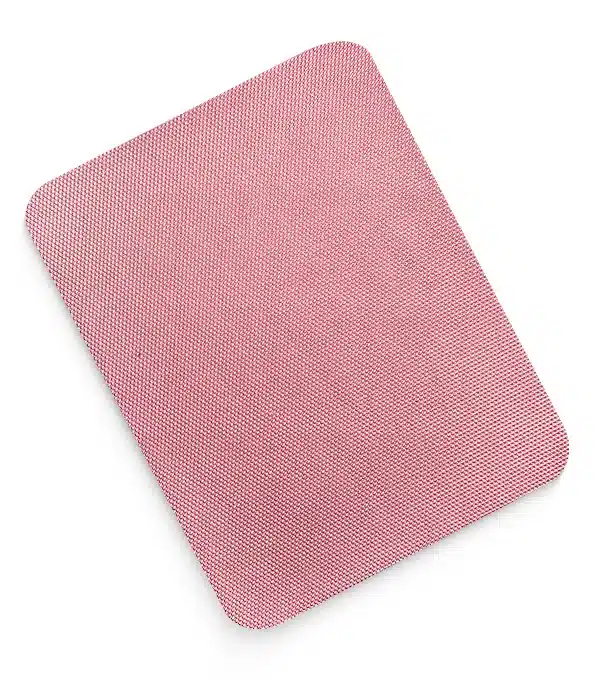

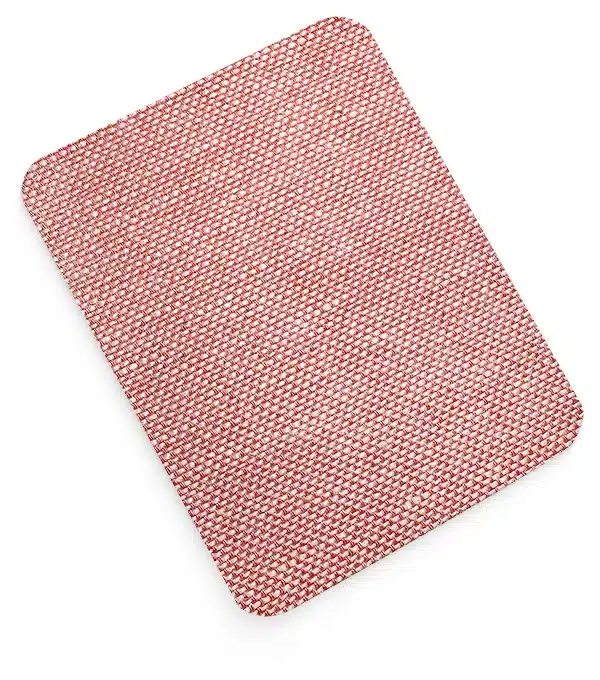

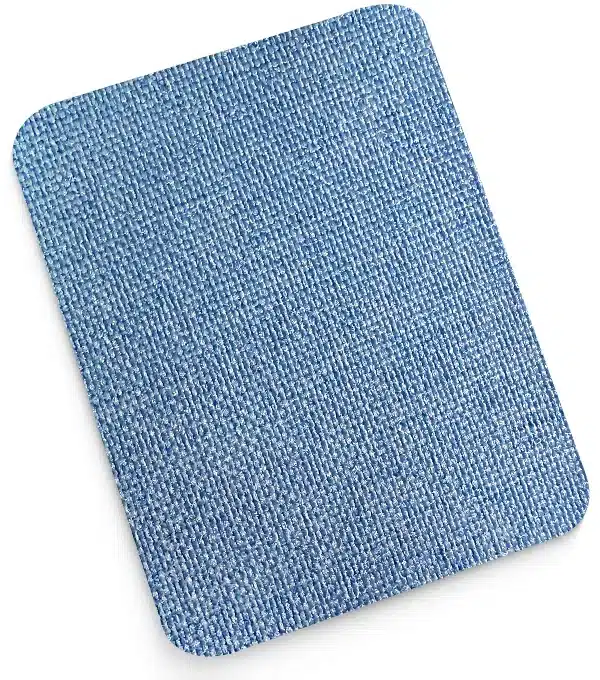

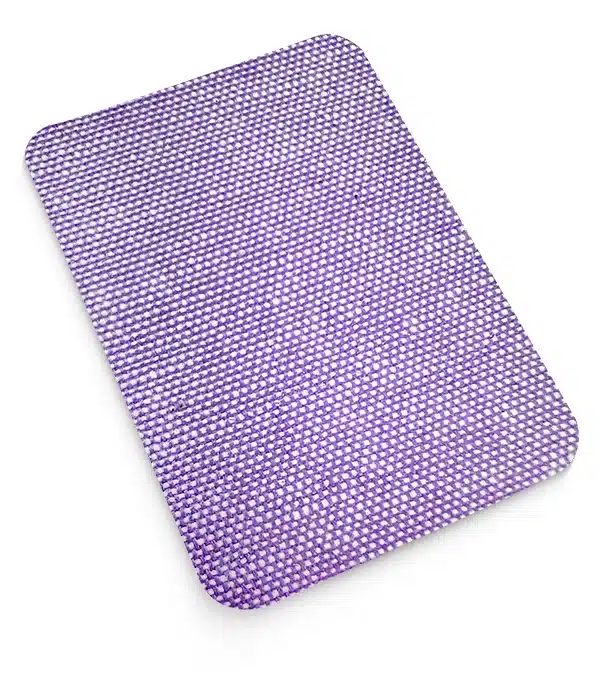

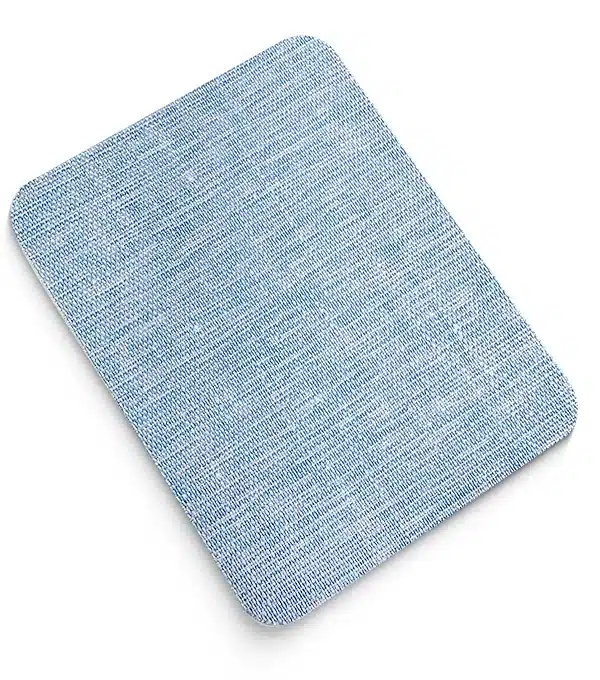

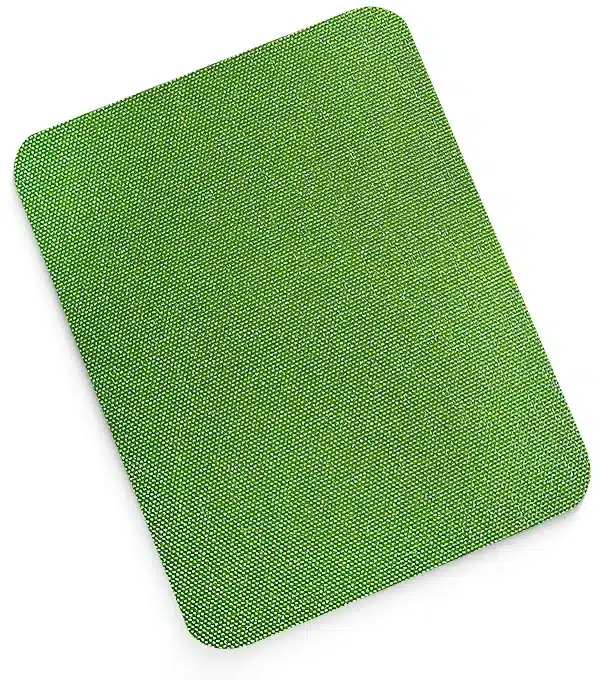

Cloth Material Gallery

We offer 14 distinctive woven-texture cloth materials, each available in a variety of colors. Every fabric showcases its own unique weave, feel, and finish—ranging from sleek and refined to bold and highly textured—so you can find the perfect fit for your project’s creative vision and practical needs.

Explore the gallery below to discover the variety of surfaces, patterns, and tones we offer for hardcover cases, slipcases, and specialty packaging.

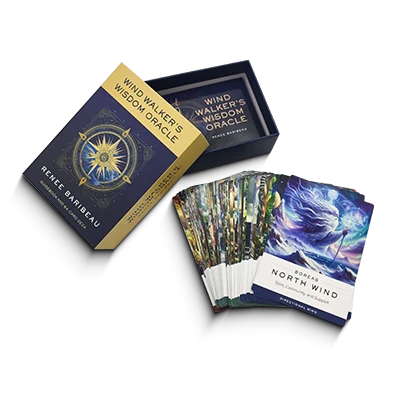

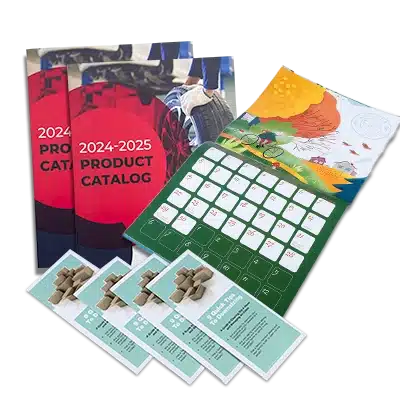

Applications

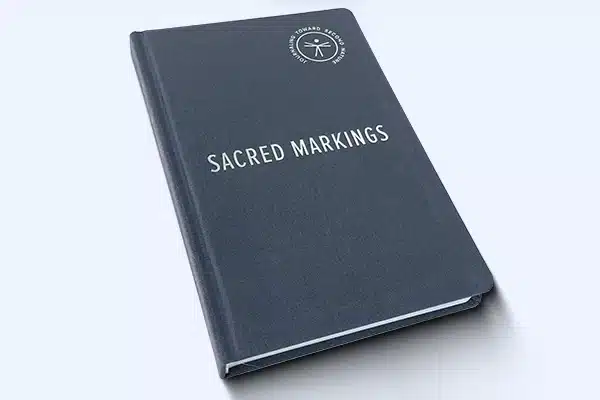

Cloth materials are typically used for:

- Hardcover book covers, providing durability and tactile quality.

- Slipcases designed to protect and complement hardcover editions.

- Limited edition or coffee table books requiring premium finishes.

- Custom journals and notebooks aimed at a refined look and feel.

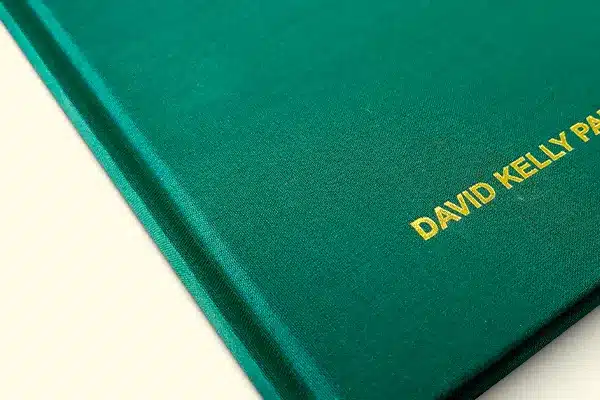

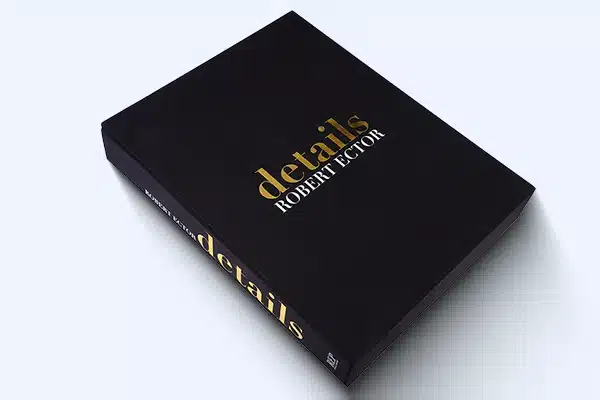

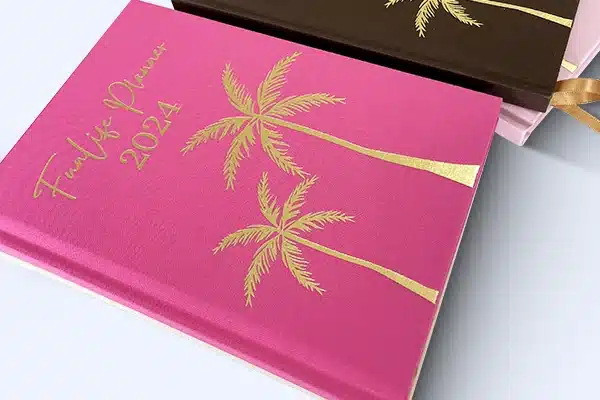

Special Finishing Options

Elevate your cloth-covered products with these premium finishing techniques:

- Foil Stamping – Available in gold, silver, rose gold, or custom colors for a striking, metallic look.

- Debossing – Choose blind debossing for subtle elegance or combine it with foil stamping for added visual impact and texture.

- Screen Printing – Delivers bold, vivid graphics ideal for logos, text, or simple patterns.

- UV Printing – Perfect for spot-color or full-color designs, including straightforward images and graphics.

- Blind Debossing with Printed Paper Inlay – A printed paper is inset into the blind-debossed area, delivering full-color detail while retaining the dimensional impression.

These finishes enhance both the visual appeal and tactile quality of your book cloth, adding sophistication, brand presence, and a premium feel to your product.

Printing & Finishing Tips on Book Cloth

We support foil stamping, debossing/embossing, and screen or UV printing on our cloth materials. For best results, please follow these guidelines:

- Color Variation – Dye lots may vary slightly; swatch samples and final production colors can differ due to natural manufacturing processes.

- Foil Stamping – Minimum line weight: 0.3 mm; avoid fine body text below 5 pt to ensure clarity and clean edges.

- Debossing – Works best with bold logos or graphics for maximum visual impact.

- Embossing – Not recommended for cloth covers, as the flexible texture reduces the raised effect.

- Screen Printing – Use vector-based artwork for sharp, clean lines and consistent color fills.

- UV Printing – On colored or textured cloth, apply a white base layer first for brighter, more vivid colors. For photographic prints, avoid overly dark or light images, and maintain strong tonal contrast for the best results.

Frequently Asked Questions

Can the color of cloth materials be customized?

Standard colors are available, and custom color matching may be possible depending on order volume and specifications.

How is the pricing for cloth-covered hardcover books calculated?

Pricing varies based on size, page count, and finishing. Please visit our cloth cover book page for detailed pricing and an online quote tool.

Are cloth samples available for evaluation?

Yes, we provide samples upon request to assist with material selection.

Can I print CMYK artwork directly on cloth?

Yes, we can print images directly onto cloth. However, the surface of cloth is not as smooth as paper. As a result, the printed image will not appear as sharp or vibrant as it does on paper. Additionally, the image may have less depth and layering on fabric. It is best to use images that are neither too dark nor too light, and slightly enhancing the overall color tone can improve the final result.

Can the color of cloth materials be customized?

No. We can’t. You need to choose the cloth color from our material stock list.

What's the difference between cloth vs printed paper wrap?

Cloth is more tactile and durable; paper wraps allow photo-quality CMYK and lower cost.