Tuck Top Snap Lock Bottom Box

We introduce the structural and style characteristics of tuck top snap lock bottom boxes and explore their best uses in retail

What Is a Tuck Top Snap Lock Bottom Box?

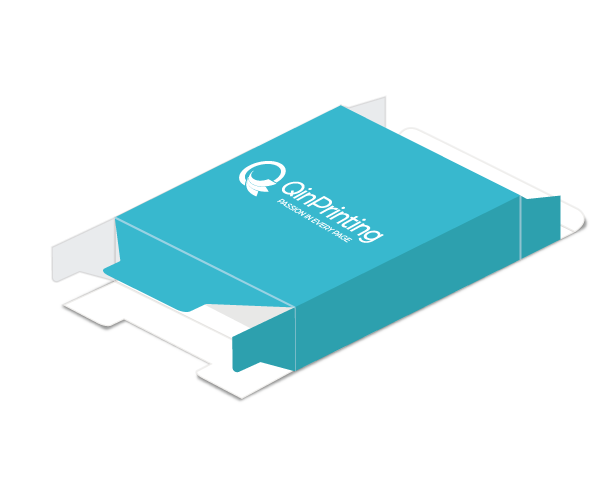

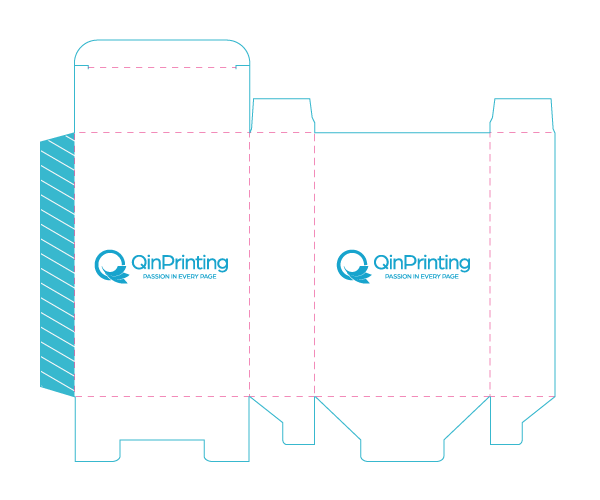

The tuck top snap lock bottom box is also called a “1-2-3 bottom box”. It comes with four flaps at the bottom that must be locked together to form the box by folding the U-shaped flap, then folding two smaller flaps inward, then folding and inserting the last flap into the U-shaped flap to lock. It may sound complicated but it’s assembled in three easy steps. They can be stored flat packed and they’re economical to produce. These boxes are sturdy and robust for handling, transportation, and storage. They also look great on shelves or in window displays.

Structural and Style Features of Tuck Top Snap Lock Bottom Boxes

Tuck top snap lock bottom boxes are designed on a single sheet of card, paperboard, or corrugated cardboard —typically 250 to 350 gsm C1S paperboard, or E-corrugated or F-corrugated cardboard —which we print with your custom artwork and text, before die-cutting, folding, and gluing to make the final carton. We can provide them pre-assembled or flat-packed for storage and self-assembly. Self-assembly time is slightly longer than the auto bottom box but they still fold and lock together easily and well.

Which Products Are Best Suited to Tuck Top Snap Lock Bottom Boxes?

Tuck top snap lock bottom boxes are an effective and economical carton style for packaging smaller, lightweight items such as cosmetics, soaps, perfumes, pharmaceuticals, and small-scale electronics. Equally, they can be used for food items, sports goods, and other products which need a more robust design, as the carton sizes can be scaled up or down according to your needs.

Tuck Top Snap Lock Bottom Box Material Options

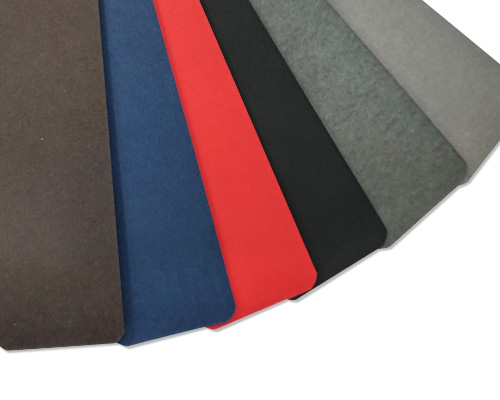

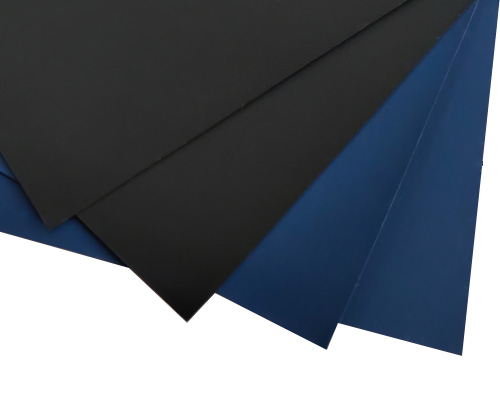

Tuck top snap lock bottom boxes are normally made of either C1S (coated one side) paper or cardboard. For larger boxes that need greater strength thicker cardboard is a sensible choice. Which materials you choose depends on your design needs and your budget. Cardboard is stronger and more rigid than paper, but C1S paper may be better for full-color printing and customization. Kraft paper is a good choice if you want a natural look or the carton is intended for eco-friendly products. Because we usually make these boxes from single-layer paperboard, they are all recyclable.

Talk to Us!

If there’s anything else you’d like to know about tuck top snap lock bottom boxes — or you have questions about the suitability of this solution for your product range — just get in touch. One of our experts will be delighted to talk you through the options and possibilities and can give you a quote should you be interested in taking things further. You can contact us either by telephone, email, Skype, live chat, or the online contact form. We can’t wait to hear from you!

Start your packaging project with QinPrinting

Explore all our different packaging choices