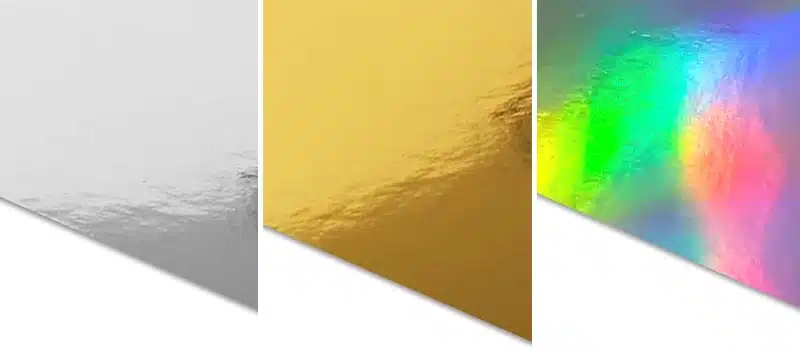

Metallic Cardstock (Gold, Silver & Silver Holographic)

What Is Metallic Cardstock

Metallic cardstock is coated paperboard laminated with a metallized PET film to create a bright, reflective surface that reads as metal. It delivers a high-impact, premium look while still converting like standard folding carton board (die-cutting, creasing, folding, gluing). We stock three production-proven options:

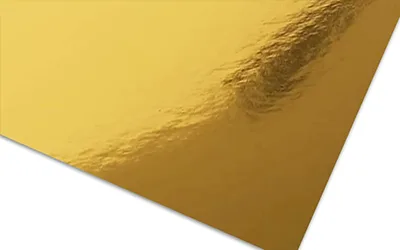

Gold Metallic (Mirror) — Metallized PET laminated to paperboard for a true mirror-gold finish. Ideal when you want a warm, jewelry-like reflectivity and strong contrast with black or deep colors.

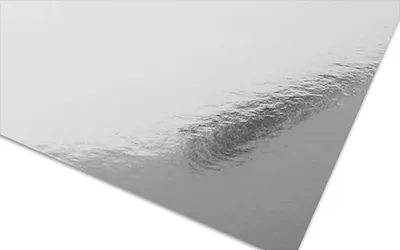

Silver Metallic (Mirror) — Metallized PET on paperboard for a clean, chrome-silver mirror look. A versatile base that can be overprinted or left unprinted for maximum shine.

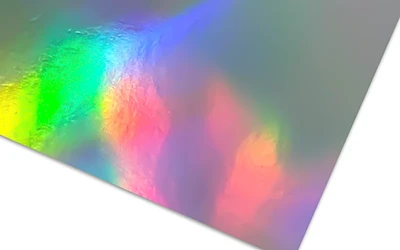

Silver Holographic (Laser) — Metallized PET with a holographic diffraction pattern that produces a rainbow effect which shifts with angle and light. Great for limited editions, gift sets, and attention-grabbing sleeves.

Metallic Cardstock Weight and Thickness

For quick quoting and structural planning, here are our most common weights and approximate calipers:

- 250 gsm — 0.35 mm

- 300 gsm — 0.41 mm

- 350 gsm — 0.50 mm

Typical applications by weight:

- 250–300 gsm (10–12 pt): Sleeves, inserts, light cartons

- 350 gsm (14 pt): Premium folding cartons, small rigid components

Note: Caliper may vary slightly by batch and supplier. If your project is tolerance-sensitive, tell us your target thickness.

The Advantages of Metallic Paper

Metallic stocks add instant premium impact and brand recognition while supporting precise converting and a wide range of specialty finishes. They’re ideal when you need a high-gloss mirror look (gold/silver) or a dynamic, angle-dependent rainbow effect (holographic) to elevate shelf presence and unboxing.

Why Choose Metallic

Choose metallic cardstock when you want high perceived value and strong contrast with print and finishing effects:

- Luxury shelf appeal for cosmetics, electronics, gifts, and specialty retail

- Bold contrast with foil stamping and emboss/deboss details

- Strong surface durability—especially with protective lamination

Printing & Finishing Options

To achieve accurate brand color and control the metallic or holographic effect, we combine offset printing with targeted white underprints and protective coatings:

- UV offset CMYK on metallic: For accurate color, we print CMYK over a white ink base (spot “White Ink” plate). Areas without white remain metallic/holographic for stronger shine.

- Spot colors & Pantone: Available; use a white underprint wherever color accuracy is critical.

- Foil stamping & emboss/deboss: Excellent contrast on metallic stocks; recommended minimum line weight ≥ 0.3 mm.

- Varnishing & coatings: Gloss varnish or sand-texture varnish (Sand UV) improves scuff resistance (note: textured finishes can soften/mute the mirror or holographic effect). Gloss preserves more reflectivity.

- Die-cutting & creasing: Clean edges with steel-rule dies; pre-scoring minimizes cracking on folds.

Production Notes

- Mirror and holographic surfaces show handling more readily—gloss or sand-texture varnish helps reduce scuffs; note that sand texture will reduce reflectivity.

- We use adhesives and coatings formulated for metallized films to ensure strong adhesion and durable finishes.

- Color behavior: The same CMYK will render differently on gold, silver, and silver holographic stocks. For the closest match to your intended color, print CMYK over a white-ink underbase. Even with white ink, expect slight variation compared with printing on standard white paper. (If exact brand color is critical, request drawdowns or press proofs.)

Design & File Setup Tips

A clear file setup helps you control where color appears as solid ink and where the metallic or holographic effect shines through:

- Provide a separate vector spot plate named “White Ink” to define where CMYK prints as solid color (over white) vs. raw metallic/holographic.

- For fine details on the white plate, add a 0.2–0.3 mm choke/trap to avoid halos.

- Minimum positive line: 0.3 mm; reverse text: ≥ 6 pt for legibility.

- Bleed: 3 mm on all sides; keep critical text/logos 3 mm inside trim and 2–3 mm away from creases and glue flaps.

Best-Use Scenarios

Metallic and holographic stocks are a smart upgrade wherever visual drama and tactile quality drive conversion:

- Folding cartons and sleeves for cosmetics, fragrance, skincare, and electronics accessories

- Gift boxes, telescoping rigid lids, belly bands, premium inserts

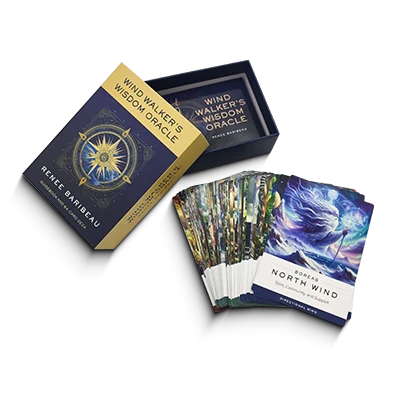

- Card-deck packaging upgrades: metallic or holographic tuck boxes, sleeves, certificates

Related Resources