SAND UV (Sand-Texture UV)

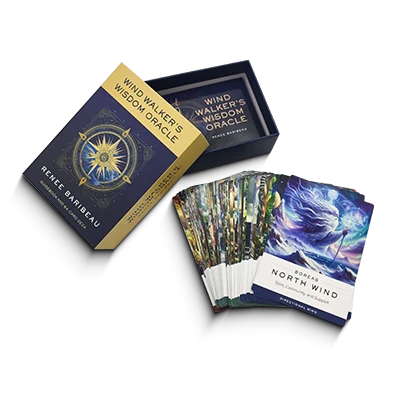

SAND UV—also called sandy UV, grit UV, or sand-texture UV—is a UV-curable clear coating applied by screen printing to create a fine, sand-like tactile texture. It’s typically used as a spot effect (select areas rather than full coverage). SAND UV adds visual interest and a premium, raised, non-slip feel to packaging, book covers, and cards. Because the coating is clear, your artwork and colors remain visible; the textured surface catches the light and is more noticeable on darker, solid backgrounds.

Best-Use Scenarios

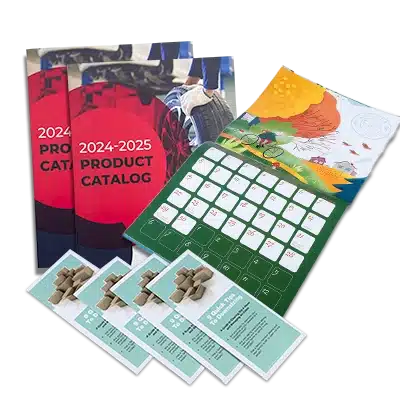

- Premium packaging (cosmetics, electronics, gift boxes): add tactile grip and extra scuff resistance on key panels or wraps.

- Hardcover dust jackets & cases: spot-apply on titles, patterns, or borders for subtle, raised contrast.

- Brand accents: logos, icon stripes, or geometric backgrounds that need a refined, anti-slip touch.

- Tactile learning tools: highlight letters, numbers, or shapes on flash cards so users can feel the forms.

- Functional high-touch zones: tray bases, lift points, pull tabs, belly bands, sleeves, and other hand-contact areas on boxes.

Artwork Setup Guide

- Create a separate file for Sand UV: Start by duplicating the original artwork file. Remove all areas that do not require Sand UV, keeping only the parts that need the effect. Fill the remaining areas with any spot color (we recommend naming it “SAND_UV” or another clear, descriptive name).

- Save files separately: Save the Sand UV file and the original artwork file as separate documents.

- Ensure perfect alignment: Make sure the Sand UV file perfectly overlaps the original artwork to avoid any misregistration.

Design Tips

- Keep clear of folds & creases: texture can crack across folds, scores, or hinge lines. Leave ≥ 3 – 5 mm from any crease or spine hinge.

- Use bold, legible details: avoid hairlines and tiny type. For best results, use text ≥ 12 pt and line weight ≥ 0.5 mm.

- Prefer vector: convert text and shapes for SAND UV to vector to preserve crisp edges and texture clarity.

- Limit large floods: SAND UV works best as an accent. Reserve it for patterns, panels, and marks rather than full-bleed coverage.

Compatibility & Combinations

- With laminations: pairs especially well with matte or soft-touch lamination for strong tactile contrast. It can run over gloss lamination, though the texture looks subtler.

- With other finishes: great next to spot gloss UV (gloss-vs-grit contrast). Keep SAND UV and foil or gloss UV in separate locations; leave a 3–5 mm gap for the cleanest look and adhesion.

- Paper types: performs best on coated papers or C1S (coated one side) stocks finished with matte or soft-touch lamination. On uncoated papers, the texture appears softer and less defined.

Materials & Suitability

SAND UV is ideal for most retail packaging and book applications. It is not intended for direct food contact. For unusual substrates or heavy textures, we recommend a press test to confirm adhesion and appearance.

FAQs

Is SAND UV the same as spot UV?

No. Spot UV is glossy and slick; SAND UV is textured and semi-matte.

Can I combine SAND UV with soft-touch lamination?

Yes—this is a popular pairing: velvety background + gritty pattern.

Can I print SAND UV over foil?

We don’t recommend printing on top of foil. Keep a 3–5 mm gap for best adhesion and appearance.

Will SAND UV change my colors?

The coating is clear. It appears more pronounced on dark solids and subtler on very light tints.

Can I use tiny text or hairlines?

Use bold shapes and larger type. Follow the minimums above for crisp texture edges.

Does it crack on folds?

Texture can fracture on creases—keep it a safe distance from scores and hinges.