One of the most important but less publicly-known aspects of book printing is the method used to bind the pages and cover together. When creating a hardcover book in particular, choosing the right binding method significantly impacts the durability, functionality, and aesthetics of the book. For offset printing — the most common printing method — two hardcover binding methods stand out: Smyth-sewn binding and PUR (polyurethane reactive adhesive) binding. The following FAQs provide key information about Smyth-sewn and PUR hardcover binding, helping you make the best choice for when you next print your hardcover books.

What is Smyth-Sewn Binding?

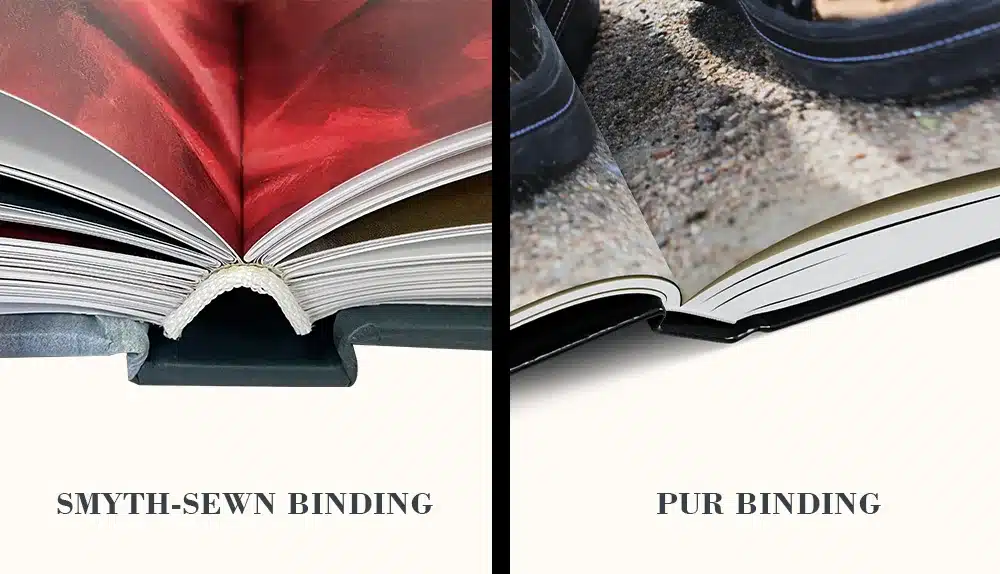

Smyth-sewn binding gets its name from David McConnell Smyth, inventor of one of the first book-sewing machines in 1868. This binding method involves sewing groups of pages, called signatures, together with thread. The sewn signatures are then attached securely to the hardcover casing, creating a highly durable and high-quality book. Smyth-sewn binding is regarded as the premium standard in offset printing, especially for hardcover books.

What is PUR Binding?

PUR binding uses polyurethane reactive adhesive — a strong, flexible glue — to directly attach pages to the spine. In recent years, PUR glue has become popular as a strong, cost-effective alternative to traditional EVA glue due to its enhanced flexibility and strength.

Smyth-Sewn Hardcover Binding vs. PUR Hardcover Binding FAQs

1. Which binding method is more durable?

Smyth-sewn binding is more durable.

2. Can both Smyth-sewn and PUR binding be used for hardcover books?

Yes, both methods can be used.

3. Which method can be used for square spine hardcover books?

Both Smyth-sewn and PUR binding can be used for square spine hardcover books.

4. Which method can be used for round spine hardcover books?

Only Smyth-sewn binding is suitable for round spine hardcovers. PUR binding cannot be used to produce books with a rounded spine.

5. Why can't PUR-bound hardcover books have a rounded spine?

PUR binding creates a firm, flat spine that cannot bend into a curved shape, making it unsuitable for rounded spine hardcovers.

6. Can I use Smyth-sewn binding for exposed spine hardcovers?

Yes, Smyth-sewn binding is ideal for exposed spine hardcovers.

7. Which binding method is better for books that need to lay flat?

Smyth-sewn binding allows books to lay perfectly flat.

8. Can PUR binding be used for large, heavy hardcover books?

No, PUR binding is less suitable for large, heavy hardcover books.

9. How long does Smyth-sewn hardcover book production typically take?

Production of Smyth-sewn hardcover books typically takes about 2–3 weeks.

10. Why is Smyth-sewn binding considered more premium?

Smyth-sewn binding provides superior durability and flexibility, alongside a handcrafted aesthetic, making it highly valued for premium publications.

11. Are there visual differences between Smyth-sewn and PUR hardcover books?

Yes — Smyth-sewn books have visible stitching along the signatures, whereas PUR hardcover books have a smooth, glued appearance along the spine.

12. Can PUR-bound books be opened flat without damaging the spine?

PUR-bound books can open relatively flat, but not as completely or easily as Smyth-sewn books.

13. Can PUR glue withstand high temperatures or humidity?

PUR glue performs better than traditional glues in humidity and heat, but can still be sensitive over prolonged extreme conditions.

14. Which binding is more eco-friendly or recyclable?

Smyth-sewn binding is generally more eco-friendly and easier to recycle compared to PUR binding.

15. Which binding requires longer production times?

In China, production times for Smyth-sewn and PUR hardcover bindings are similar. In the United States and Europe, Smyth-sewn typically takes longer due to more labor-intensive processes.

16. Why is PUR binding more common in the U.S. and Europe?

Labor costs in the U.S. and Europe are higher, making PUR binding a more cost-effective solution in comparison to Smyth-sewn binding.

17. Why is Smyth-sewn binding more popular in China?

China has an abundance of equipment and skilled labor, making Smyth-sewn binding relatively cost-effective and efficient.

18. Can I switch binding methods mid-project?

Yes, the binding method can be switched as long as printing has not yet started. After the printing process has begun, switching is no longer possible due to different binding-edge specifications.

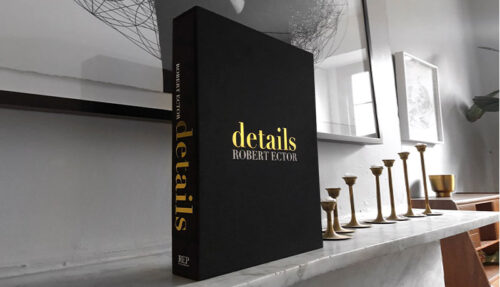

19. What is the best binding method for collectible or keepsake hardcover books?

Smyth-sewn binding is best for collectibles due to its superior quality and durability.

20. Is PUR binding suitable for books intended for occasional use?

Yes, PUR binding is suitable for moderate or occasional use.

21. Which method is better for archival purposes?

Smyth-sewn binding is recommended for archival purposes.

22. Does the choice of binding affect the final book weight?

No, binding choice typically does not significantly impact the final weight.

23. Which binding works better for books with thick paper or multiple signatures?

Smyth-sewn binding is better suited for thick papers and multiple signatures.

24. Is Smyth-sewn binding available for short-run offset printing?

Yes, Smyth-sewn binding is available for short-run offset projects.

25. What types of books are best suited for PUR hardcover binding?

PUR binding is suitable for textbooks, manuals, journals, and other books that are frequently used.

26. Can I customize the thread color in Smyth-sewn binding?

Yes, thread color customization is possible.

27. What type of binding is better for hardcover books with over 300 pages?

Smyth-sewn binding is generally recommended for books over 300 pages.

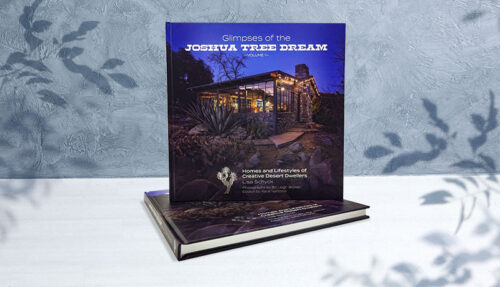

28. Which binding is better for coffee table books with large image spreads?

Smyth-sewn binding is better for coffee table books with large, panoramic spreads.

29. Is PUR binding suitable for children's hardcover books?

Yes, PUR binding is suitable if the books are to be lightly used. For more heavy usage, Smyth-sewn binding is recommended.

30. What's the minimum page count recommended for Smyth-sewn hardcover books?

The minimum recommended page count is typically around 24 pages.

31. Is there a price difference between PUR and Smyth-sewn binding in China?

In China, Smyth-sewn binding is often more economical due to readily available machinery and skilled labor.

32. Are there spine width limitations for either binding method?

PUR binding is more suited for narrower book spines, while Smyth-sewn works well for various spine widths.

33. Which binding method is better for books printed with heavy ink coverage?

Smyth-sewn binding handles heavy ink coverage better, reducing potential spine stress.

34. Is PUR glue visible along the spine in hardcover books?

Generally not; PUR glue is usually hidden within the spine.

35. What binding do libraries prefer for their hardcover books?

Libraries prefer Smyth-sewn binding for its superior durability and longevity.