Designing a board game takes imagination, patience, and persistence. But moving from a handmade prototype to a professionally printed run is another skill entirely. Independent creators and small publishers often don’t realize how much changes when quantity goes up. Production needs to match quality expectations, budget limits, and retail or crowdfunding goals.

If you’re preparing to scale, here’s what you need to know, broken into concrete, manageable steps.

When to move beyond print-on-demand

Print-on-demand services are fine for early play-tests and pitch samples. You can order as few as one or two copies. But unit prices are high. A single game might cost you $30 or more to print, and it won’t look or feel like a retail-quality product.

You should consider offset printing once you plan to produce 500 or more copies. This is where unit prices start to drop sharply. For example, printing 500 games might cost $10 per unit. Printing 2,000 copies might drop that to $5 per unit.

The break-even point depends on your goals. If you plan to sell your game, even on a small scale, offset is usually the better option.

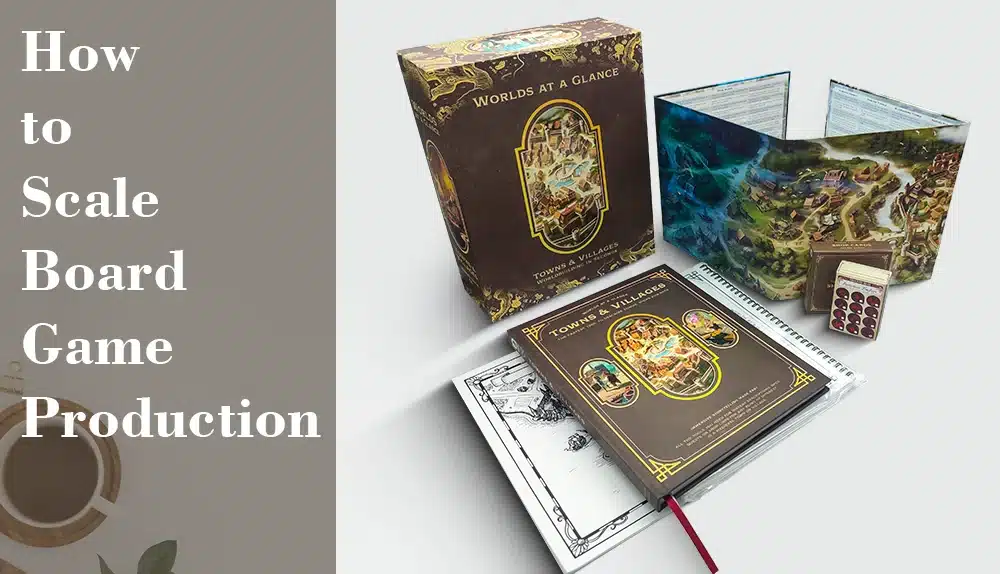

Scaling custom board game production at-a-glance

| Topic | Key Details |

|---|---|

| When to Scale Up | Offset printing becomes cost-effective at 500+ units. Unit cost drops significantly at higher volumes. |

| Materials to Finalize | Game board, cards, tokens, dice, custom pieces, box, and rule book. All components must be print-ready. |

| Rule Book Options | Saddle-stitched; typically printed in full color on 128gsm or 157gsm gloss or matte paper. |

| Prepress Requirements | CMYK color, 300 DPI resolution, 3mm bleed, vector dielines. QinPrinting provides templates and checks all files. |

| Proof Types | Digital proofs are fast and free; physical proofs confirm materials and color. Most clients use both. |

| Quality Control | QinPrinting runs test batches, calibrates colors, and performs spot checks throughout production and packing. |

| Packaging and Logistics | Games are shrink-wrapped, carton-packed, palletized, and labeled. Split shipments and fulfillment prep available. |

| Why QinPrinting | Full-service support, clear communication, technical expertise, and scalable production for publishers, businesses, and self-publishers. |

Choosing the right materials at scale

Custom board games include many components. You’ll need to finalize materials long before production begins. Each choice affects both cost and player experience.

At QinPrinting, we help creators choose the right specifications for every component:

- Game board: Most use 2 mm or 2.5 mm grayboard, wrapped in printed paper with a matte or gloss finish. Larger boards may need to fold into quarters rather than halves to fit in the box.

- Cards: 300 gsm or 350 gsm black core stock is standard for retail-quality decks. Cheaper options are available but less durable.

- Tokens and punchboards: These are printed on grayboard and die-cut. We provide standardized dielines and guidance on spacing.

- Dice, meeples, and custom pieces: Choose from stock parts or request custom components in plastic or painted wood.

- Box: We produce both corrugated and rigid setup boxes, most often in a lid-and-bottom style. Our team provides exact templates for artwork with correct bleed and safety zones.

- Rule book: Most rule books are saddle-stitched and printed in full color on coated paper. Popular options include 128 gsm or 157 gsm gloss or matte stock. We recommend matching the paper type to the game’s tone—gloss for bright or modern designs, matte for softer or historical themes.

Every project at QinPrinting includes detailed consultations so your game meets both design and production goals.

Managing prepress: getting files ready

Before anything goes to print, your files must be correct. This is called prepress. QinPrinting’s prepress team checks every file, flags issues, and sends proofs before production begins.

To avoid delays, follow these guidelines:

- Set color mode to CMYK, not RGB.

- Use 300 DPI resolution for all artwork.

- Add 3 mm bleed on all sides.

- Keep text at least 3 mm inside the trim line.

- Use vector files for dielines and layout.

We provide templates for all standard components. Our team answers questions and offers feedback before printing begins.

Proofs: digital vs physical

Once your files are approved, we send a proof. This can be digital or physical.

- Digital proofs are fast and free. They show layout, text placement, and image orientation.

- Physical proofs show color accuracy, paper texture, and assembly. These are ideal for a final check before large runs.

Most clients start with a digital proof, then confirm with a physical proof before mass production. We recommend both, especially for first-time publishers.

Quality control for mass production

At QinPrinting, we apply strict quality control at every stage.

- We run a test batch before full production.

- Color calibration tools match proofs with press output.

- Our production staff perform spot checks throughout assembly and packing.

If an issue arises during production, we stop and fix it. We maintain clear records and samples for every batch, and we’ll repeat any step that doesn’t meet quality standards.

Packaging and logistics

Board games need sturdy packaging. Most are shrink-wrapped, boxed in labeled cartons, and stacked on pallets. We use double-corrugated shipping boxes and include standard labeling with item codes, quantities, and weights.

If your order ships to multiple regions, we can split shipments by destination. For crowdfunding projects or global retail distribution, we can group and pack items according to fulfillment center needs.

We also offer assembly services. If your game includes cards, inserts, bags, or extra parts, we can pack each box with all components, ready for shipment.

Working with QinPrinting

We specialize in custom board game production. Our team works with publishers, businesses, and self-publishers at every stage. We help you make technical decisions, manage color accuracy, and get a professional product on time and on budget.

If your game includes complex or non-standard components, we’ll develop custom tooling and walk you through samples and prototypes. We’ve printed everything from educational games for universities to Kickstarter projects with thousands of backers.

We’ve worked with clients across North America, Europe, and Asia. Our English-speaking support team responds quickly and clearly. Every project is managed by real people, from quote to final delivery.

Final advice before you scale

Scaling a board game isn’t just about printing more. It’s about producing a finished product that reflects your work and meets your audience’s expectations.

Before committing to a large run, consider a pilot batch. Use it for marketing, reviews, and distributor samples. We can help you adjust quantities, swap components, or revise packaging as needed.

Then, when you’re ready, QinPrinting will produce your game at scale with full support from start to finish.

FAQs

1. What is the minimum order quantity for offset printing at QinPrinting?

We recommend a minimum of 500 units for offset printing. This is the point at which pricing becomes more cost-effective compared to digital or print-on-demand services.

2. Can I request a sample or prototype before committing to a full production run?

Yes. We offer both digital and physical proofs. Physical samples are especially helpful to confirm color, material feel, and component alignment before mass production.

3. What file formats do you accept for board game artwork and layouts?

We accept print-ready PDF files with CMYK color, 300 DPI resolution, and 3mm bleed. Vector files are required for dielines and layout accuracy. We provide templates for all components.

4. How long does production take once files are approved?

Standard production time is 3 to 5 weeks, depending on the number of components and total quantity. Shipping time varies by destination and method.

5. Can QinPrinting handle kitting and full assembly of my board game?

Yes. We can assemble all components—cards, tokens, inserts, rule books, and boxes—into final retail-ready packaging, shrink-wrapped and carton-packed for delivery.

6. What if I want to include non-standard items like metal coins or magnetic boxes?

We handle custom components regularly. These items require special tooling and longer lead times, so contact us early in your planning process.

7. Do you ship internationally and support multi-region fulfillment?

Yes. We ship worldwide and can divide orders for fulfillment centers in different regions. We also label cartons by region and follow custom packing instructions when needed.

Talk to us. We're here to help!

Let us know about the game project you’re working on and would like to scale up. We’ll get you a quote, a schedule, and a plan that works. Just shoot us an email at [email protected] or call us on +1 951 866 3971, and we’ll be delighted to discuss your needs.