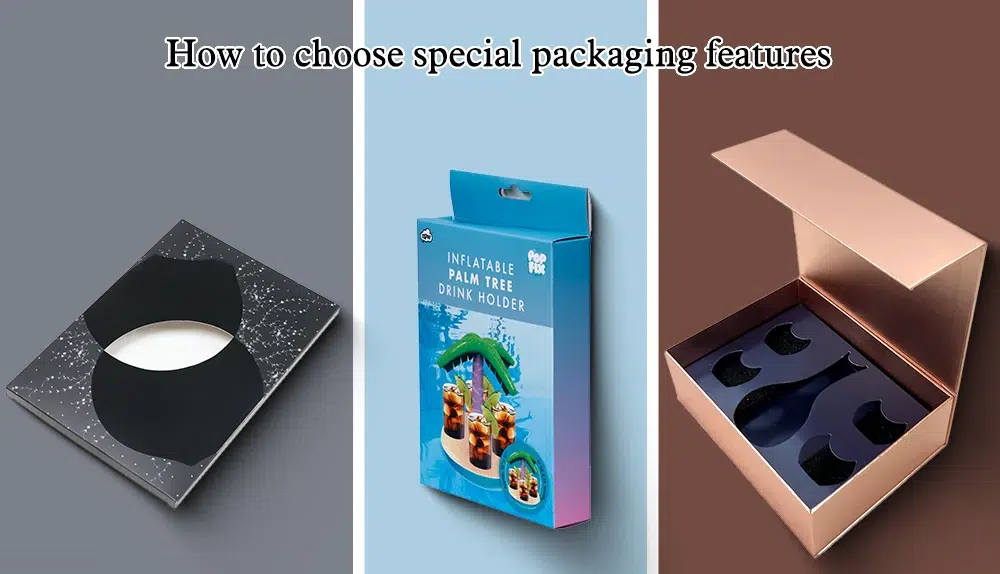

Packaging design is often thought of in terms of materials and graphics, but sometimes, it's the small structural details that make all the difference.

Features like die-cut windows, custom inserts, or built-in handles aren’t just decorative—they’re functional solutions to practical needs. When done well, they can help your packaging stand out, keep products safe, and make things easier for your customers. At QinPrinting, we’ve worked with businesses across industries to incorporate these features into custom box designs that work as well in practice as they do on the shelf.

Quick guide

| Eco-Friendly Strategy | Key Benefits |

|---|---|

| Use recycled or kraft paper | Reduces environmental impact; enhances brand image |

| Soy or vegetable-based inks | Renewable, reduces pollution, improves recycling |

| Minimize waste in design | Saves resources, lowers costs |

| Sustainable packaging | Reduces landfill waste, appeals to consumers |

| Eco-friendly production | Decreases harmful emissions and waste |

| Efficient shipping practices | Reduces carbon footprint, saves costs |

| Transparent communication | Builds consumer trust, boosts brand loyalty |

The practical benefits of structural features

Adding thoughtful structural features to your packaging can solve specific problems and add value that goes beyond surface appeal. These features are especially useful for brands looking to create a more functional, interactive, or luxurious customer experience.

- Windows: A die-cut window lets customers see the product before they open the box. This can be particularly valuable for items where appearance matters, like food, cosmetics, or toys. In retail, it can help build trust and encourage sales. For e-commerce, windows add a tactile dimension, making the unboxing more engaging. Windows can be left open or covered with clear PET film for protection. Because cutting a window into a box removes some material, we take care to reinforce the surrounding areas so that strength isn’t compromised. You can explore more about our die-cut box options here.

- Inserts: Without inserts, products can slide around during shipping, risking damage and making the presentation look messy. Inserts are designed to hold items snugly in place and are often custom-shaped to match your product. We make inserts from corrugated cardboard, rigid board, foam, or molded pulp depending on your product’s weight, fragility, and look. For example, electronics often use foam inserts for shock absorption, while cosmetics might use cardboard for a sleeker appearance. Learn more about custom box inserts.

- Handles: Useful for larger boxes, handles make carrying easier for customers. But a handle is more than a hole in the box; it needs to be strong enough to hold the weight without tearing. We often recommend reinforcing the handle area with double layers or choosing a corrugated board with higher strength. For added comfort, we can design handles with rounded edges or protective film.

These small additions can make a big difference to how customers interact with your product—both in-store and at home.

Special closures and textural finishes

Closures and finishes can transform your packaging from something purely functional to something memorable and premium. These features often appeal to brands in the luxury, gift, and bespoke product sectors.

- Magnetic closures: These are popular for high-end products such as jewelry, cosmetics, and presentation kits. Magnetic closures offer a clean, secure seal without visible fastenings. The magnets are hidden within the structure of the box, keeping the look smooth and uncluttered. They also offer repeatable opening and closing without wear, adding to the longevity of the packaging. We typically pair magnetic closures with rigid boxes—you can see examples of rigid magnetic boxes we produce.

- Tabs, slots, and locks: These features allow boxes to be closed securely without needing tape or glue. They’re practical for products that require quick assembly or for businesses looking to present a more refined finish. We can design these closures for both folding cartons and corrugated boxes, depending on your product and packaging needs. This is especially useful in environments where packaging must be assembled quickly and efficiently.

- Embossing, debossing, and foil: Adding texture to your packaging makes it stand out, not just visually, but to the touch. Embossing raises parts of the design, debossing pushes them down, and foil adds a metallic sheen to logos or text. These techniques help highlight your branding and elevate the perceived value of your product. We offer a range of special finishes that can be combined to great effect.

Balancing form and function

Each added feature changes the dynamics of the box design. It’s essential to think through how these details will affect the strength, cost, and practicality of your packaging.

- Strength: Features like windows or die-cuts naturally reduce the strength of a box, but we can adjust the design—using thicker board, adding reinforcement strips, or changing the shape—to keep it robust. This is particularly important for heavier or fragile items.

- Assembly: Some features require more time to assemble or special tools. For example, magnetic closures add steps to the process, while tabs and locks might streamline it. When planning your packaging, it’s worth thinking about the time and labor involved in putting it together.

- Cost: Extra features often increase production costs, but they don’t have to be extravagant. We’ll work with you to decide which elements are worth the investment and where a simpler solution might do the job just as well. If you want to explore your options, feel free to contact us for a quote.

FAQ: Innovative packaging features

Can you add windows to any type of box?

We can add windows to folding cartons, rigid boxes, and some corrugated designs. The size and shape depend on the product and the box’s strength.

What materials do you use for window coverings?

PET film is the most common. It’s clear, durable, and can be heat-resistant if needed for certain finishes.

Are inserts always custom-made?

Not always. Standard inserts work for many products, but we can custom-cut them to fit unusual shapes or create a premium look.

Do handles increase shipping costs?

Not necessarily. They add very little weight. The main factor is the box size, not the handle.

How strong are magnetic closures?

Is there a minimum order for boxes with these features?

Do these features delay production times?

Talk to us. We're here to help!

Structural features in packaging are about more than aesthetics. When used thoughtfully, they solve real problems—whether that’s showing off a product, making sure it arrives safely, or simply making the customer’s life easier. At QinPrinting, we’ve helped businesses of all sizes figure out which features are worth investing in, and how to design them right. If you’re thinking about adding something special to your packaging, we’re ready to help you make it work. Just shoot us an email at [email protected] or call us at +1 530 238 5010, and we’ll be delighted to discuss your needs. We look forward to helping you get the best deal possible both in terms of pricing and product quality.