When I walked into a print shop for the first time in 1990, I never imagined that one day I would be working with authors, publishers, and creators all over the world. Back then, I was simply grateful to have a job I genuinely enjoyed: making words and images look beautiful on paper.

More than thirty-five years later, I’ve worked as a typesetter, production manager, sales representative, factory general manager, and now founder of QinPrinting, an offset printing company serving clients globally. The technology has changed dramatically—but the fundamentals of good printing have not.

In this article, I’d like to share a few lessons I’ve learned along the way.

Lesson 1: Typesetting Taught Me That Details Are Everything

My career started in typesetting. Back then, it meant long hours, careful eye work, and endless patience. I learned:

- How line spacing affects readability

- How incorrect margins or gutters can make a book uncomfortable to read

- How a tiny typo or misaligned element can ruin an otherwise perfect job

From those early days, I understood that printing quality starts long before the presses run. Good print is built on good files, and good files are built on respect for typography, layout, and the reader’s eye.

Even today, when clients send us files, I still examine them with a “typesetter’s brain.” I automatically check:

- Are margins and safe zones correct?

- Is small text readable?

- Are there any obvious errors that will show up after binding or trimming?

- Do you have specific brand standards, Pantone colors, or compliance requirements we need to follow?

That habit has saved many projects from disappointment.

Lesson 2: Production Management Taught Me How the Factory Really Works

Later, I moved into production management. This is where I learned to connect design and theory with real machines, real paper, and real time.

In production, you quickly learn that:

- A beautiful design paired with the wrong material will fail on the press.

- Every material choice—paper weight, coating, binding—has consequences for cost, durability, and schedule.

- You must always plan for tolerances: paper stretches, ink behaves differently on different stocks, and binding and cutting have their own variances.

- Different surface treatments produce different results depending on the paper.

My job was to balance quality, cost, and deadlines. I had to coordinate operators, schedule press time, and solve problems quickly when something went wrong.

This experience still shapes how I advise clients today. When I recommend paper or binding options, it’s not theoretical—it comes from years of watching what happens on the factory floor.

Lesson 3: Sales Taught Me to Listen Before I Talk

Many people think “sales” is just about convincing clients to place an order. For me, it became another kind of education.

As a sales representative, I learned that every client has a story behind their project:

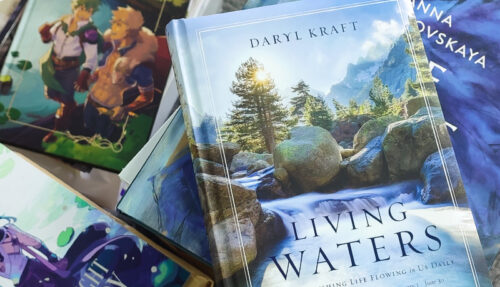

- An author printing a first book after years of writing

- A small publisher trying to keep costs under control

- A crowdfunding creator balancing promises to backers with a fixed budget

- A global brand ensuring every packaging detail aligns with their strict brand guidelines and compliance standards

If I talked too much about machines and specifications, I could easily miss what really mattered to them.

So I trained myself to listen first:

- What is your real priority—price, quality, or schedule?

- Who is your end reader or customer?

- What matters most to you—paper feel, color accuracy, or binding durability?

- Is this a one-time project or the start of a long-term series?

Only when I truly understood their goals could I suggest the right format, quantity, and materials. This mindset later became one of the core values at QinPrinting.

Lesson 4: 20 Years as a Factory General Manager Taught Me About Responsibility

I spent about 20 years as a general manager of a printing factory. That role changed the way I saw everything.

Suddenly, I was responsible for:

- The livelihood of many employees and their families

- The trust of long-term clients who relied on us for consistent quality

- Major decisions on equipment investment, workflow, and quality-control systems

When something went wrong—color inconsistency, delayed shipment, binding issues—it was my responsibility to face clients, find the root cause, and fix the process so it wouldn’t happen again.

This period taught me:

- Quality is a system, not a single step.

- Training and communication are as important as machines.

- The best factories are built on trust—within the team and with clients.

Lesson 5: Starting QinPrinting Taught Me How to Serve the Global Market

After decades in the industry, I decided to start my own company: QinPrinting. We focus on offset printing for clients around the world, especially in North America, Europe, Oceania, and beyond.

The vision was simple but ambitious:

- Combine high-quality Chinese manufacturing

- With transparent communication and service that international clients expect

- And a genuine passion for books, packaging, and printed products

We built an English website, created online quote calculator, and adapted our internal systems to work with different time zones, currencies, and shipping methods. We also had to train our team on international client expectations:

- Responding quickly to every inquiry is essential—clients need to know there’s a real person behind every message, not a bot.

- Why color consistency across reprints is critical.

- Why packaging and damage prevention during long-distance shipping matters.

- Why clear communication—even when there’s a problem—is always better than silence.

Today, we work with self-published authors, indie publishers, game creators, artists, and brands worldwide. Every project still follows the same core principles I learned as a young typesetter: respect for details, respect for the craft, and respect for the client.

Key Lessons I Would Share with Anyone Printing Today

Looking back at 35+ years in the printing industry, here are a few simple lessons:

- Files are the foundation. Good printing begins with good preparation—correct bleeds, resolution, color mode, and layout.

- Communication beats assumptions. Tell your printer your goals, deadlines, and constraints. Let them help you find the right solution.

- Cheap, good, and fast rarely come together. You usually need to choose two. Being honest about your priorities leads to better results.

- Long-term relationships matter. When printer and client work together over multiple projects, both sides get better at predicting and preventing problems.

- Technology changes, but care doesn’t. We now use CTP plates, automation, color-management systems, and global logistics. But in the end, it’s still about people who care about every page.

I entered this industry because I loved printing. After all these years, that hasn’t changed. If anything, the feeling is stronger. There is something uniquely satisfying about holding a finished book or box in your hands and knowing that many quiet, invisible decisions made it possible.

What lessons have shaped your work over the years? I’d love to hear your story.