Don't know how to choose between lamination or varnishing for your book cover? You will once you've read this!

As a major international offset printer working with mainstream and independent publishers alike, we understand the importance of creating a book that not only captivates readers with its content but also entices them with its physical appearance. One of the key factors that contributes to the overall appeal of a book is its cover. The quality, design, and finish of the cover can make a significant impact on a reader’s perception of the book’s value and professionalism.

As both a reader’s first impression and a lasting physical keepsake, a book cover is essential to a book’s success, setting expectations for quality, value, and content. At QinPrinting, we work with publishers and authors who understand that the cover finish — whether laminated or varnished — can make all the difference in enhancing both the book’s visual impact and durability.

In this post, we’ll explain everything you need to know about two of the most popular finishing options for book covers: lamination and varnishing. We’ll break down what each entails, highlight key differences, and walk through the benefits and ideal uses for each. Whether you’re looking to protect your book’s cover from wear or create an eye-catching, tactile design, understanding these finishing options will help you make the best choice to bring your book to market.

What is lamination?

Lamination is a process that involves applying a thin film of 0.012 to 0.020 mm thick transparent plastic to the surface of a printed material, such as a book cover. This film acts as a protective layer, safeguarding the cover from damage and enhancing its visual appeal. Let’s explore the different laminations and their unique characteristics.

1. Gloss lamination: bright and eye-catching

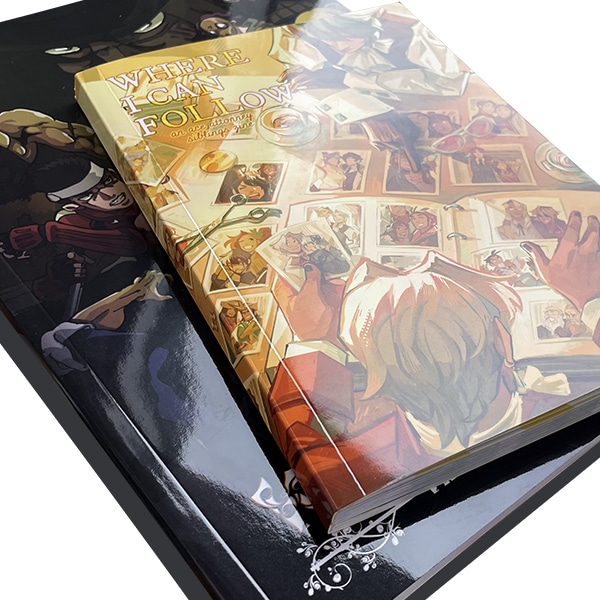

Gloss lamination is a popular choice for book covers because of its ability to create a vibrant and glossy finish. The shiny surface of gloss lamination instantly catches the reader’s eye and adds a touch of sophistication to the book. It enhances the colors and contrasts of the design, making it visually striking. Gloss lamination is well-suited for books that aim to stand out on bookstore shelves or online marketplaces.

2. Matte varnish: subtlety and elegance

If you’re looking for a more refined and understated appearance, matte lamination might be the perfect choice for your book cover. With its non-reflective surface, matte lamination exudes a sense of sophistication and luxury. It enhances the longevity of the cover by protecting it from scratches, tears, and general wear and tear. Matte lamination is often favored for high-end projects, art books, or publications that require a touch of elegance.

3. Soft touch lamination: a luxurious experience

Soft touch lamination, also known as “peach skin” lamination, creates a velvety-soft feel on the surface of the cover. It adds a luxurious tactility to your book, making it irresistible to touch and handle. Soft touch lamination enhances the colors and details of the design while providing protection against scratches and fingerprints. This finish is ideal for books that aim to convey a sense of exclusivity and high quality.What are the advantages of lamination for book covers?

Advantages of lamination

Lamination offers many benefits that go beyond aesthetics. Let’s inspect the advantages of laminating your book covers.

- Enhanced protection: Lamination provides an extra layer of protection, guarding the cover against everyday wear and tear, stains, and spills. It acts as a shield, preventing tears, scratches, and fading, ensuring that your book maintains its pristine condition for a long time.

- Durability: By laminating your book covers, you increase their strength and durability. The laminate film reinforces the cover, making it more resistant to bending, creasing, or tearing. This is especially important for books that are frequently handled or transported.

- Professional appearance: The polished look achieved through lamination instantly elevates the perceived quality of your book. Whether you choose gloss or matte lamination, the result is a professional and high-quality appearance that will attract readers and give your book a competitive edge.

- Easy maintenance: Laminated covers are easy to clean and maintain. Any marks or spills can be wiped off effortlessly without damaging the cover or the underlying print. This makes laminated book covers suitable for a variety of environments, including libraries, schools, or coffee tables.

- Recyclable: Despite being a plastic coating, a laminated paper is fully recyclable at the end of its life and so “close the loop” in production, helping to protect the environment and reduce landfills.

Besides book covers, lamination is a popular choice for catalogs, manuals, brochures, and flyers. Now you know what lamination is and the range of options available, along with its beneficial qualities both aesthetically, practically, and environmentally, let’s look at the key alternative for finishing your book cover: varnish.

What is varnishing?

Varnishing is another technique that can significantly enhance the appearance and durability of book covers. It involves applying a protective liquid coating to the surface of the printed material, creating a layer of transparent gloss or matte finish. Varnishes come in a range of glazing constituents: press varnish, UV coating, and aqueous coating. At QinPrinting, we use aqueous coating only as part of our ecological commitment, as it doesn’t produce toxins or leave residues in the environment. After the application, varnish is then cured under heat.

While varnishing can be an excellent choice for your book covers, it is also widely used in packaging boxes, other paper products, and stickers. It’s especially well adapted to food, medicine, and cosmetics packaging. Its glossiness is somewhere in between gloss lamination and matte lamination and has added characteristics of safety and reliability.

How to choose between lamination and varnishing

Now that we have explored the benefits and applications of lamination and varnishing, you might be wondering which option is best for your book covers. The choice ultimately depends on your specific needs and preferences. Consider the following factors when making your decision:

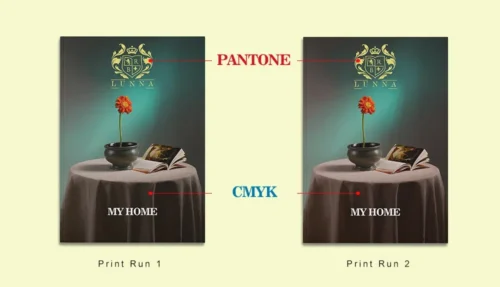

- Desired look and feel: Think about the aesthetic you want to achieve for your book covers. If you prefer a mirror-bright eye-catching appearance, a gloss lamination or gloss varnish might be the right choice. For a more refined look, matte lamination or matte varnish can provide the desired effect.

- Level of protection: Assess the level of protection your book covers require. If your books will be frequently handled or exposed to potential damage, lamination offers a higher level of durability and resistance to wear and tear. Varnishing provides a protective layer against scratches and fading, which is adequate for everyday situations.

- Budget considerations: How much have you got to spend? You need to consider your budget when deciding between lamination and varnishing. While both processes add value to your book covers, varnishes are often less expensive than laminates.

Spot UV: adding highlights to laminated or varnished covers

Suited to both matte laminated and varnished surfaces, to take your cover to the next level, you can consider incorporating spot UV. This technique involves applying a glossy varnish to specific areas of the cover, creating a contrast between the matte surface and the glossy highlights. Spot UV adds depth and texture to the design, giving it a professional and visually appealing finish. It is effective in drawing attention to important elements, such as titles, logos, or graphic elements. The coating cures under ultraviolet light, hence the name.

Lamination vs. varnishing

Lamination and varnishing are both processes that can transform your book covers from ordinary to extraordinary. They provide not only protection but also enhance the aesthetic appeal of your books. Whether you choose gloss, matte, or soft-touch lamination, or a gloss or matte varnish, the decision should be based on your desired look, level of protection, budget, and intended use. And if you select a matte option, you can add a special touch of magic with spot UV coating, too.

By investing in these processes, you can create book covers that not only capture the attention of readers but also convey a sense of professionalism and quality. So, explore the possibilities of lamination and varnishing to elevate the appearance and durability of your next book project.

Talk to us!

At QinPrinting, we have almost 30 years of success in the printing industry. We’ve worked with innumerable mainstream and independent publishers to print high-quality, world class books with every attention to detail. We have the latest printing technologies at our disposal and a truly comprehensive range of lamination and varnishing capacities. At our state-of-the-art facility, our expert team of highly qualified printers and technical staff work round the clock with unrivaled dedication to fulfill all our customer’s orders to the highest standards.

If you’re ready to print a world class book with a professional cover — whether a hardback or a softback — then talk to us first. We pride ourselves not only in our technical competence, market and industry knowledge, and rigorous quality control, but also in our tailored, personalized customer service. We treat every client as unique and deserving of the closest attention and support regardless of the project or the size of the order.

Talk to us today to discuss your specific needs and ask us for a free, no-obligation quote. Our vision is always to combine products of exceptional quality with dedicated customer service at an unbeatable price point. We can’t wait to help you make your next book cover the most eye-catching yet!