Custom Reverse Tuck End Boxes

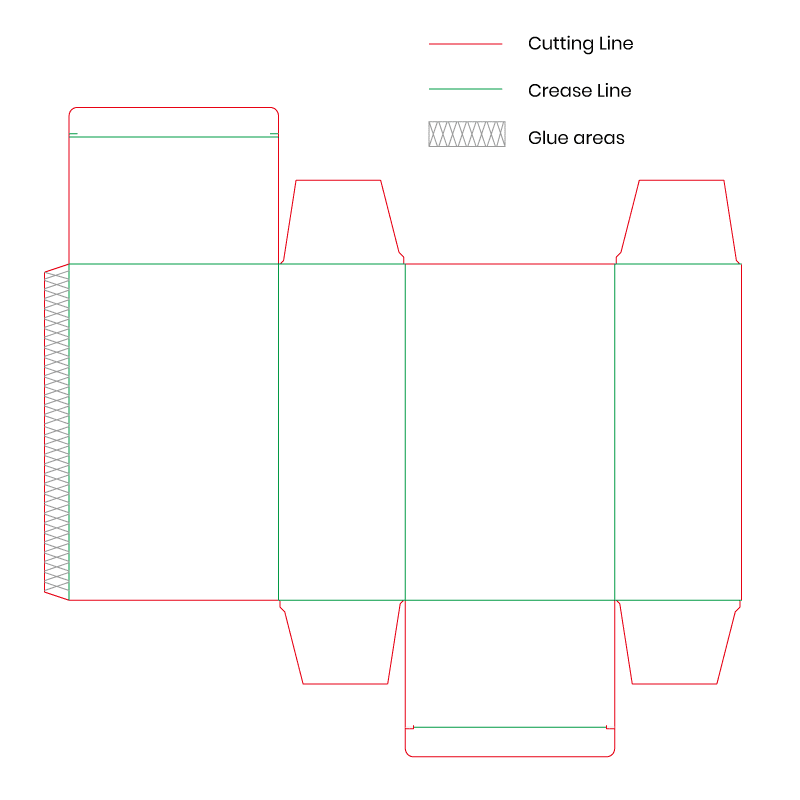

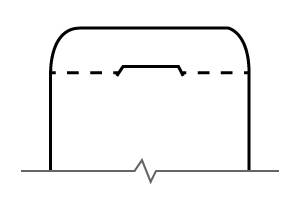

If you’re looking for a versatile yet practical way to package your items, try our custom reverse tuck end boxes! In this style, the box’s tuck flaps close in opposite directions — one at the top and one at the bottom — to create a secure, easy-to-open structure. At QinPrinting, we use our high-end technology and years of industry experience to provide you with custom reverse tuck end boxes designed and printed exclusively for your brand.

Custom Reverse Tuck End Boxes Instant Quote

Custom Additional Box Features

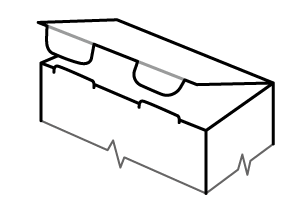

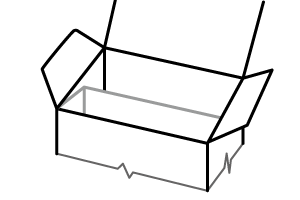

Design your paper boxes with custom structural features, to securely hold your product and create a unique unboxing experience.

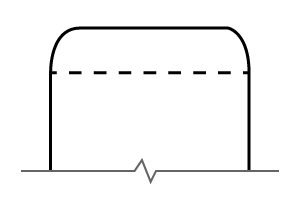

Friction Fit Tuck Flap

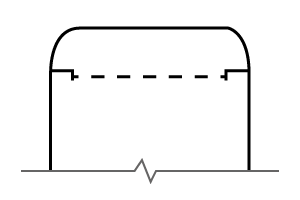

Slit Lock Tuck Flap

Lift Tab

Thumb Cutout

Tongue Lock

Tab Lock

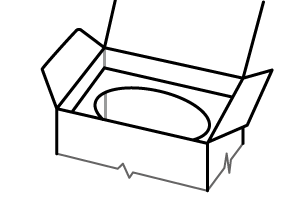

Integrated Insert

Integrated Partition

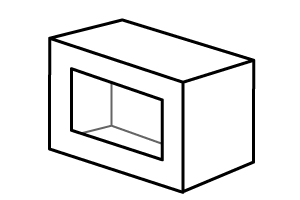

Window Cutout

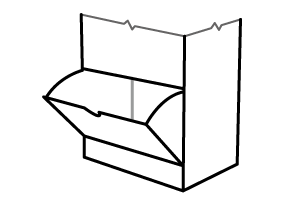

Dispenser

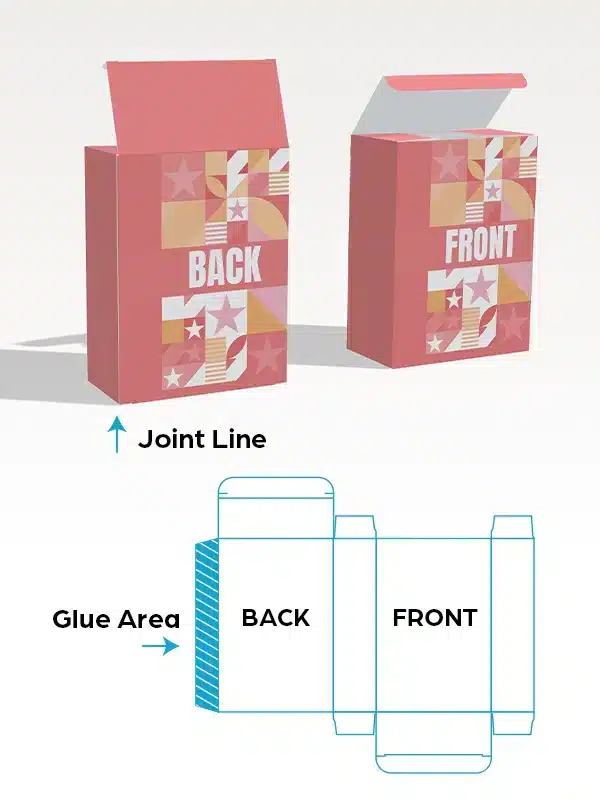

Reverse Tuck End Boxes – Front and Back Orientation

For reverse tuck end boxes, the panel connected to the top tuck flap is usually considered the back side, while the opposite panel is the front side. You can download a standard template of this layout directly from our website.

If you prefer the panel connected to the top tuck flap to be the front side, please contact us to request the corresponding template.

The main difference between these two versions lies in the gluing position. The glued side usually leaves a visible joint line, which should face the back side of the box for the best appearance.

Cardstock Choices

We offer a wide range of premium cardstock options to keep your packaging sturdy and attractive. Choose coated, colored, textured, metallic, soft touch, or pearlescent cardstock to showcase your products and reinforce your brand identity.

C1S Cardstock

This coated cardstock provides a smooth finish, excellent for vibrant printing and detailed graphics.

Available weights: 250–400gsm

Clean surface, consistent print results

Textured Cardstock

Choose from White or Off-White Linen, Oxford, and Blanket textures.

Each features a subtle, tactile pattern and comes in sturdy weights — around 350gsm (17pt / 0.435mm) — adding a luxurious, high-end feel to your packaging.

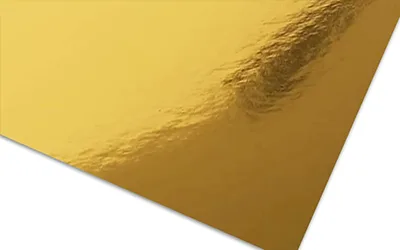

Metallic Cardstock

Gold Metallic Cardstock

A luxurious gold finish that shines and stands out. Available in 250gsm, 300gsm, and 350gsm for different levels of rigidity.

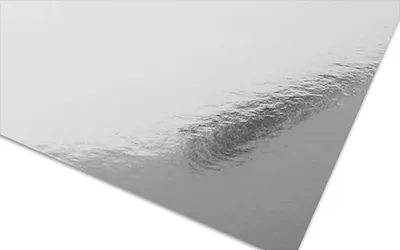

Silver Metallic Cardstock

Sleek, polished silver for premium packaging. Available in 250gsm, 300gsm, and 350gsm

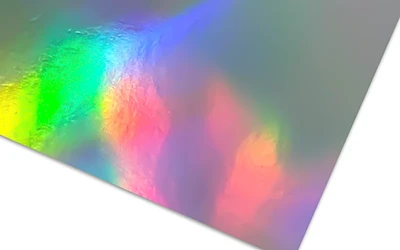

Holographic Metallic Cardstock

Dynamic holographic shimmer for a high-end, eye-catching look. Available in 250gsm, 300gsm, and 350gsm

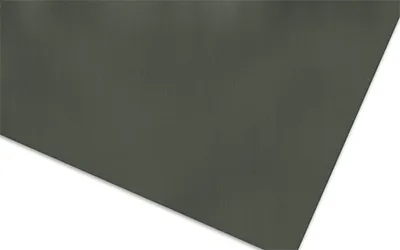

Plain Cardstock

Solid-color cardstocks in black, dark gray, off-white, white, brown, navy, red, and other colors weigh approximately 330gsm and are about 17pt (0.43mm) thick, offering a smooth, sturdy surface for minimalist or bold packaging designs.

Soft-Touch Cardstock

Velvety soft-touch cardstocks in black, warm gray, white, brown, navy, red, and other colors weigh around 290gsm and 350gsm. Their soft, luxurious feel enhances the premium quality of your boxes.

Pearlescent Cardstock

White Pearlescent Cardstock

Bright white with a subtle shimmer, adding elegance to any box. Available in 350gsm.

Off-White Pearlescent Cardstock

A warm pearly glow with a soft, refined look. Available in 370gsm.

Cream Pearlescent Cardstock

Delicate cream tone with a gentle shimmer. Available in 315gsm.

A Wide Range of Custom Finishes

Elevate your custom boxes with these premium finishes:

Lamination and Varnish Options

Gloss Lamination

Creates a shiny, reflective surface that makes colors appear more vibrant.

Matte Lamination

Provides a smooth, non-glossy finish with an elegant and modern look.

Soft Touch Lamination

Adds a velvety, silky texture for a premium, tactile experience.

Scratch-Resistant Gloss Lamination

Combines a glossy shine with long-lasting scratch protection.

Scratch-Resistant Matte Lamination

Maintains a refined matte look while offering extra resistance to scratches.

Gloss Varnish

A clear coating that enhances brightness and gives your packaging a glossy finish while providing light protection.

Matte Varnish

A subtle, low-sheen coating that protects while keeping a classic matte appearance.

Sand Varnish

Available with UV offset printing; adds a fine, sand-like matte texture.

Special Finishes

Foil Stamping

Foil stamping adds metallic accents to your packaging, giving a luxurious and eye-catching look. Perfect for logos, brand names, or decorative elements.

You can choose from our common colors here, or explore more options on our foil stamping page.

Spot UV

Applies a glossy coating to specific areas of your design, creating contrast and highlighting key details.

Sand UV

A textured UV finish that provides a tactile, matte-like effect with subtle shine.

Debossing

Impresses your design into the paper, creating an elegant, recessed effect.

Embossing

Raises elements of your design above the surface for a sophisticated 3D effect.

Textured Finish

Adds a unique tactile surface to the paper, enhancing the sensory experience and premium feel of the packaging.

Printing Options

We match the printing process to the surface and color of the box paperboard to achieve the best results, including CMYK offset, Pantone spot colors, metallic inks, UV printing, screen printing, and other advanced techniques.

CMYK Printing

Standard full-color printing for vivid images and smooth gradients.

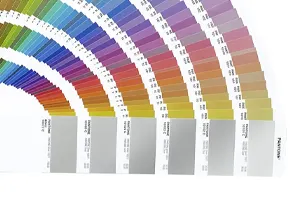

Pantone Color Printing

Pantone spot colors ensure exact color matching for logos or brand elements.

Metallic Pantone Color Printing

Pantone metallic inks add a shiny, reflective effect to your design. Great for luxury packaging.

UV CMYK Printing

Combines a glossy shine with long-lasting scratch protection.

White Ink Printing

Prints solid white ink on colored surfaces, often used as a base layer or for standout white designs.

Spot Color Screen Printing

Spot Color Screen Printing delivers thick, vibrant ink with excellent opacity and tactile depth.

Can’t find exactly what you want? Contact us and our team will help you produce custom paper boxes tailored to your product. Let’s create the perfect packaging together!

Start in Just a Few Steps

Best Uses for Reverse Tuck End Boxes

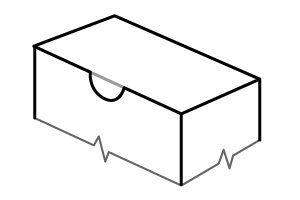

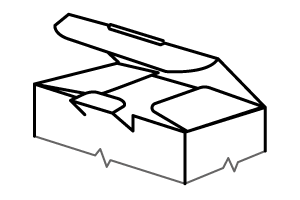

Reverse tuck end boxes close at the top and bottom with flaps that tuck into opposite panels. This layout helps the box stay square and stable, and it reduces rubbing on the same panel during opening and closing. Because of that, reverse tuck end boxes are a reliable choice for retail packaging and for products that need a cleaner presentation over repeated handling.

Reverse Tuck End Boxes for Secure Retail Packaging

Reverse tuck end boxes are commonly used for pharmaceuticals, supplements, personal care items, fragrances, candles, and small consumer goods. Since the top and bottom tuck in opposite directions, the opening motion feels smoother and the panels stay neat—especially helpful for products that may be opened more than once before purchase. The large, uninterrupted front and back panels also give you plenty of room for branding, compliance text, and product details.

For most retail applications, 300–400 gsm premium paperboard provides excellent print quality and stiffness. If the box is larger or needs extra protection during shipping, E-flute or F-flute corrugated can be a strong upgrade.

Reverse Tuck End Boxes for Auto-Packing and Heavier Items

Compared with straight tuck end boxes, reverse tuck boxes are often preferred for taller or slightly heavier products because the opposing tuck direction helps maintain structure and reduces stress on one side of the box. They also work well on packing lines, since the box closes neatly without forcing both ends into the same panel. This makes reverse tuck end boxes a practical option for items like dropper bottles, small hardware sets, grooming products, and multi-piece kits that need added stability inside the carton.

For both corrugated and cardboard versions, you can add features such as a tear strip, thumb notch, and inside printing to create a smoother unboxing experience and keep address labels and shipping marks from interfering with your design.

Reverse Tuck End Box Assembly Tips

Pre-fold all score lines to keep edges sharp and speed up packing. Open the box, fold in the small side flaps, and close the bottom tuck flap first. After inserting the product from the top, close the top tuck flap in the opposite direction.

Because the top and bottom tuck into different panels, make sure your artwork is oriented correctly so the front panel faces forward when the box is closed. For smoother high-volume packing, pre-breaking creases and keeping cartons nested can improve line speed and consistency.

Why Work with QinPrinting?

Eco-Friendly Options

FSC-certified materials are available so you can create sustainable packaging without compromising on quality or appearance.

Affordable Pricing

Get premium-quality custom boxes at competitive prices, helping you save costs while still delivering impressive packaging.

Worldwide Delivery

We provide reliable global shipping, ensuring your boxes arrive safely and on time, no matter where your customers are located.

Fully Customizable

We offer complete customization for your reverse tuck end boxes. Choose between any size, material, printing technique, and box structure to perfectly fit your product and brand vision. At QinPrinting, we’ll help you create a unique box design that you can be proud of.

Exceptional Service

Our team provides one-on-one support throughout the process. We assist with box structure design, review your files, and offer sample production to ensure your packaging meets your expectations. We’re here to make the entire experience smooth and worry-free.

FAQs

What is your minimum order quantity (MOQ)?

Our MOQ for reverse tuck end boxes is 300 units.

What is the turnaround time?

Production usually takes 10-20 days after proof approval, plus shipping time.

Where is your factory located?

Our factory is based in Shanghai, China, with convenient access to both sea and air freight. You are always welcome to visit our facility.

Do you have the capacity for large-volume production?

Yes, we regularly handle runs of tens of thousands or even millions of boxes, ensuring consistent quality and reliable delivery.

Can I add multiple finishes on one box?

Yes, you can! For example, you might choose embossing + foil stamping, debossing + spot UV, or holographic paper + gold foil. Many of our clients combine two or more finishes to create boxes that stand out.

You can request samples to see and feel the options before placing an order.

Can I print on the inside of the box?

Yes! Depending on your design needs, we can print on only the outside, only the inside, or on both the inside and outside. Please request a quote if you would like double-sided printing.

Do you offer dieline templates?

Yes. You can download free dielines directly under our online quote tool or visit our template page. For special box shapes, just contact us and we’ll prepare a custom dieline.

Do you provide samples before mass production?

Yes. We offer hard proofs, digital proofs, and finished samples so you can confirm colors, finishes, and materials before we start full production.

Do you ship worldwide?

Yes, we ship globally via sea and air freight. Our logistics partners ensure safe delivery to your destination.

Do you offer design services?

We don’t provide design services. However, if you print with us, we’ll check your artwork for free to ensure it meets our printing requirements.

Can you make reverse tuck end boxes with a perforation or tear-off section?

Yes, perforations can be added for easy opening or dispensing features.

What file formats do you accept for artwork?

Please provide your artwork as a PDF file with 3 mm bleed, CMYK colors, embedded fonts, and high-resolution images.

Can I order reverse tuck end boxes with eco-friendly paper?

Yes, we provide sustainable options such as FSC-certified stock. Many clients choose eco-friendly custom reverse tuck end boxes to highlight their brand’s commitment to sustainability.

What Our Customers Say

Real stories from customers who worked with us to create custom packaging they’re proud of.

I couldn’t be happier with my experience working with QinPrinting. From start to finish, their team was responsive, professional, and truly invested in helping me bring my vision to life. I printed my first edition of a 58-card deck (complete with a custom magnetic box) and the results were stunning.

The color accuracy, matte finish, and premium cardstock all exceeded my expectations. Every detail shows real craftsmanship. The communication was outstanding too; they provided clear updates, design templates, and guidance at every stage.

What impressed me most was how personal the process felt. Even though they’re a large-scale printer, they treated my small-batch creative project with care and respect.

If you’re looking for a reliable, high-quality printer for custom card decks, packaging, or creative projects, I can’t recommend QinPrinting enough. I’ll absolutely be printing with them again for my next production run!

Susan!!!! These books are SOOOOOOO beautiful! I don't think we could have dreamed how joyful it would be to open the box and find such care for and beautifully printed books. This was a special day -- we hope to have many more like it.

Thank you for fielding so many questions. Your patience with us (well, me) was so kind. You and your team have gone above and beyond for us.

Gratefully,

MAC

Most of all, we are so grateful for Nelson’s support throughout the entire process. He was consistently helpful, communicative, and detail-oriented — truly a pleasure to work with. Every step was made easier thanks to his guidance and care. We couldn’t have asked for a better experience!

Highly recommend both the product and working with Nelson. We’ll definitely be back for future projects.

A special thanks to Nelson, who went above and beyond by sending us videos of the printed books and samples before shipping to ensure everything was perfect. His attention to detail and dedication gave us great peace of mind.

We had a children’s book printed and the final product was absolutely beautiful. The print quality, vibrant colors, sturdy binding, and professional packaging exceeded our expectations. Delivery was timely and the pricing was very competitive, especially for the high level of quality and service we received.

We were so impressed that we didn’t hesitate to place a second order with them and once again, everything was flawless.

If you're looking for a reliable, high quality, and customer focused printing company, QinPrinting is the one to go with. Highly recommended!

Kricket Moros

Talk to Us

Ready to create your custom reverse tuck end boxes? Use our online quote calculator or talk to our packaging experts to start designing your boxes today. Our team will guide you from template download to final shipment.