Trying to decide between matte, gloss, or other lamination for your custom boxes? Here's what you need to know

Boxes Printed by QinPrinting

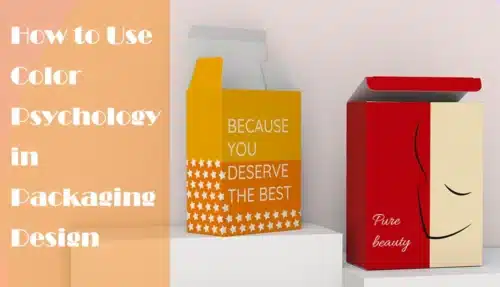

The power of first impressions

Okay, imagine picking up a beautifully packaged product. It could be anything inside, it doesn’t matter. But the box feels smooth, understated, and elegant in your hands — something about it suggests exclusivity. Now, picture another package, again it doesn’t matter what’s inside: but this time it’s sleek, reflective, and vibrant, catching the light as you turn it. Each creates a different experience, influencing your perception of the brand and the product inside even before you open it.

That’s the power and importance of lamination. When you’re designing custom-printed boxes, choosing between matte and gloss lamination is way more than just an aesthetic decision — it affects the durability, the cost, and even the sustainability of your packaging solutions. So, which one is better for your business? The answer to that depends on several factors. But we can help you work it out. Let’s break it down.

Quick comparison

| Feature | Matte Lamination | Gloss Lamination |

|---|---|---|

| Look & Feel | Soft, sophisticated, non-reflective | Shiny, vibrant, high-contrast |

| Readability | Reduces glare, ideal for text-heavy designs | Enhances colors and images, can cause glare |

| Best For | Luxury, eco-conscious brands, muted aesthetics | Bold, attention-grabbing designs, retail packaging |

| Cost | Same price | |

What is lamination, and why does it matter?

Essentially, lamination is a thin plastic film applied to printed surfaces to enhance durability and appearance. Lamination can be integrated into the offset printing process or be added after printing depending on the specific needs of the design. It acts primarily as a protective layer, helping to prevent wear and tear , scuffs and scratches, even resisting liquid spillages and humidity, while also influencing how the design looks and feels. So, whether you’re selling cosmetics, electronics, gourmet foods, luxury goods, or anything else, the type of lamination you choose plays a significant role in how your customers and potential customers perceive your brand.

But with two major options — matte and gloss —available to you, it’s essential to understand the strengths and trade-offs of each in order to make the right decision for your brand and budget.

Matte lamination

Look and feel

Matte lamination gives packaging a smooth, muted finish with no shine or glare. This creates a more subtle and refined look then gloss that exudes luxury and exclusivity. It works particularly well for brands that want to project a high-end, modern image without being flashy. It can be combined well with metallic foil stamping and spot UV highlighting for special finishes that really stand out from the run-of-the-mill retail box. A variation is soft-touch lamination which has a velvety peachy texture if you want an especially tactile experience for your customers.

Durability & practicality

- Resistant to fingerprints and smudges, making matte ideal for boxes that will be handled frequently.

- Less prone to scratches and scuffs compared to gloss, as imperfections are less noticeable.

- However, matte finishes may show oil stains or dirt more than gloss and they are less water resistant, depending on the material substrate used.

Best use cases

- Luxury and boutique brands — Cosmetics, skincare, premium chocolates, high-end electronics and jewlry, etc.

- Eco-conscious brands — Matte finishes often pair well with natural textures and minimalist packaging made of recycled materials and kraft papers.

- Minimalist and high-end branding — If your design is typography-focused or relies on subtle details, matte enhances the effect. If a bright, colorful photographic image is central to your needs, matte is worth considering but you may find the colors and vibrancy somewhat dulled by it.

Gloss lamination

Look and feel

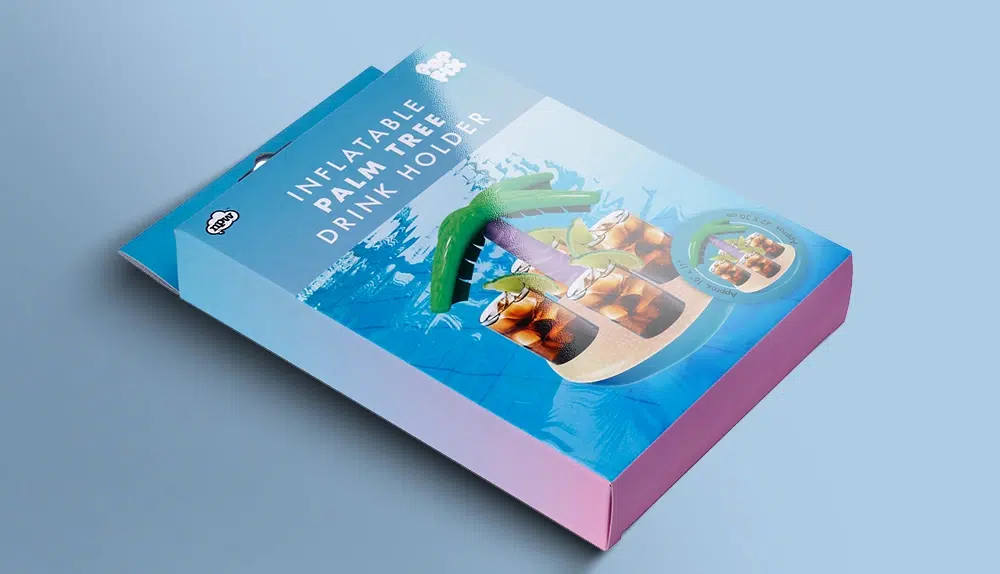

Gloss lamination has a highly reflective, shiny surface that makes colors really “pop” and images, especially photographs, appear more vibrant and dynamic. It enhances contrast, too, so that logos, graphics, and other essential imagery really stand out — making it perfect for retail environments where attention-grabbing packaging is essential and the competitive stakes are high.

Durability & practicality

- More resistant to moisture and spills, making it a great choice for food, beverage, and health products or those which may be kept in higher humidty locations such as in the bathroom.

- While gloss lamination is the most durable, it tends to show fingerprints, smudges, and scratches more easily than matte and these blemishes can’t really be rectified. However, minor liquid spillages cna just be wiped clean with a cloth.

- The added gloss can make some text harder to read under direct light due to reflections and shimmer.

Best use cases

- Retail and e-commerce packaging — Gloss lamination helps packaging pop on shelves and in product photography for your catalogs and printed marketing material inserts.

- Bold, colorful branding — Ideal for children’s toys, snacks, teen cosmetics, and any design that relies on vivid graphics.

- Food and beverage packaging — The extra protection against moisture makes gloss a practical choice in many cases.

Which one is more budget-friendly?

Cost differences between matte and gloss lamination are typically minor to be honest, but a few factors can influence pricing:

- Gloss lamination is generally more cost-effective because the process is faster and uses less specialized coatings.

- Matte lamination can be slightly more expensive, especially if you opt for specialty finishes like soft-touch matte lamination (which gives a velvet-like feel) or add features like spot UV highlights.

- Large-volume orders often minimize these cost differences, however, making the choice more about branding and your target market than budget.

Which is more sustainable?

Both matte and gloss laminations involve plastic coatings, which can make recycling more challenging. Although the films are extremely thin and most recycling centers accept laminated papers without difficulty. It’s also worth noting:

- Matte lamination has more sustainable options, such as biodegradable matte finishes that improve recyclability.

- Gloss lamination is sometimes more durable, meaning the packaging lasts longer and protects products better, reducing waste.

For brands focused on eco-friendly packaging, water-based coatings or no-lamination options may be worth considering.

How to choose the right lamination for your brand

If you’re still undecided, it may help to ask yourself these key questions:

- Do you want a luxurious, premium feel? → Go with matte.

- Is durability and moisture resistance a priority? → Choose gloss.

- Will the box be frequently handled? → Matte helps hide fingerprints.

- Do you want bold, high-contrast visuals? → Gloss enhances colors and shine.

FAQs

Q1: Can I combine matte and gloss finishes on the same box?

Yes! Using spot UV coating, you can apply gloss to specific areas on a matte surface for a striking contrast that highlights logos or key design elements.

Q2: Is matte or gloss better for luxury packaging?

Matte is typically preferred for high-end, luxury packaging due to its soft, elegant feel. However, some luxury brands use gloss to create a modern, high-impact look.

Q3: Which lamination is more resistant to wear and tear?

Gloss is generally more resistant to moisture and scratches, but matte hides minor scuffs better.

Q4: Does lamination affect printing quality?

Yes! Gloss enhances colors, making them more vibrant, while matte slightly mutes colors for a more subtle effect. This can impact how your design appears in print.

Which one is better?

The truth is, as you’ll have realized by now, there’s no one-size-fits-all answer to the question — it depends on your brand identity, product type, and practical needs.

- Choose matte if you want a sophisticated, high-end feel and a finish that resists fingerprints.

- Choose gloss if you need vibrant, eye-catching packaging that stands out on store shelves.

If you’re unsure which finish is best, you can request samples from us or get in touch to consult with QinPrinting’s packaging experts.

Talk to us. We can help.

Need help designing the perfect custom-printed box? Contact us today for expert guidance and high-quality lamination options tailored to your brand. Just shoot us an email to [email protected] or call us on +1 226 789 2909 and we’ll be delighted to do all we can to help you.